Crane Runways & Crane Runway Structure Overview for All Types of Cranes

What is a crane runway? Crane runway is a key component of an overhead traveling crane system, on which the single girder bridge or double girder bridge moves. The crane runway can be supported by self-supporting columns.

What are the components of a crane runway system ?A top running bridge crane, either single or double girder, designed with the bridge on top of the runway, is the most important component of an overhead traveling crane runway system. This system is best suited for a shop or warehouse that requires the most efficient use of overhead space.

Aside from the aforementioned, what is the purpose of a crane? A crane is a machine that can lift and lower goods as well as move them horizontally. It is usually equipped with a hoist rope, wire ropes or chains, and sheaves. It is mostly used to lift heavy objects and carry them to different locations.

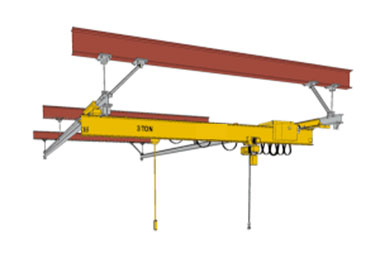

Also, what exactly is an underhung crane? An underrunning crane, sometimes known as a "underhung" crane, moves the bridge up and down the runway using wheels supported by the bottom flange of the runway beam. For lighter duty and lower-capacity applications, under running cranes are most typically equipped with a single girder configuration.

What is a runway beam?In industry, runways are commonly used to provide a track on which a lifting device can be mounted to allow loads to be raised, lowered, and moved along the runway's course.

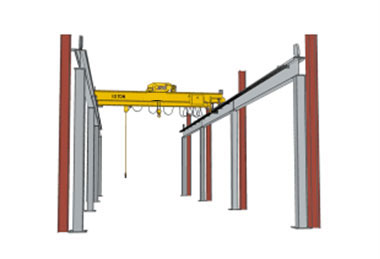

Top running crane runway

Top-running single-girder cranes and top-running double-girder cranes commonly use top-running crane runway systems. In addition, some speciality crane systems are built with a top-running runway system in mind. Top-running crane runway systems can be supported in a variety of ways. The most frequent techniques of sustaining a top running crane runway are from a hauch (which is affixed to a side of a building column) or from a freestanding structure.

Under hung crane runway

Under hung single girder and under hung double girder crane runway systems are used to mount the cranes. An under-hung runway can also be used by most speciality crane systems. For example, the runway may be mounted directly to the bottom of the building structure or an independent structural system could be used (if the building design allows for the extra loading). Alternatively, hanger rods can be utilized to alter the runway's height by suspending it from an existing structure.

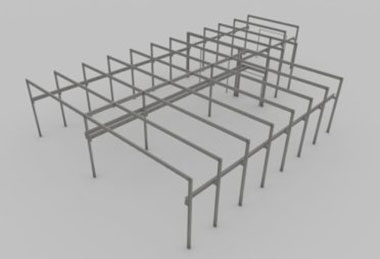

Designs of crane runway steel structure

Custom crane runway systems and supporting structural steel can be designed, engineered, and manufactured to meet the needs of any customer.

- Our fabricated steel systems include, but are not limited to, the following items:

- Underhung systems require headers, hangers, beams, and truss support.

- For top running systems, there are haunches and runway beams.

- For top-running and underhung cranes, free-standing constructions are available.

- Overhead material handling equipment need general support steel.

- Existing steel structures are being reworked.

- Platforms, catwalks, structure braces, railings, safety guards, etc.

Top running crane runway

Under running crane runway

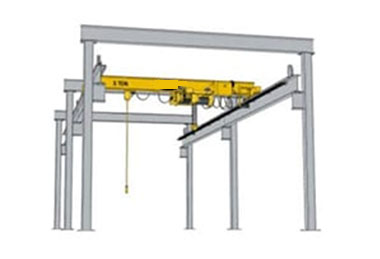

Free standing crane runway

Free standing crane runway

Free-standing Crane Steel Structure

A freestanding structure is one that is not supported by the ground and can be constructed to fit almost anywhere. Top-running and under-hung runways, as well as monorail and enclosed track systems, can all be created with these systems. If the building structure cannot withstand the crane's added load, freestanding structural steel solutions are frequently utilised. No bracing is used in the construction of these freestanding systems.

Freestanding systems can be designed with column bracing that ties back to the floor (knee braced structure) or with bracing that ties back to the structure of the building (semi-freestanding structure). The knee braced runway and the semi-freestanding runway both utilize less steel, making them a more cost-effective system. Concrete footings may be required in most freestanding constructions to support the system's weight.

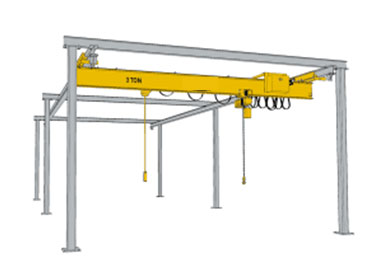

Top Running Workstation Bridge Crane Runway

Because no bracing is required and there are only four support columns, the workstation runway is simple to build. Its modular design facilitates relocation and the extension of the runway. Pre-engineering keeps costs down when compared to other options.

Freestanding Crane Runway

The Freestanding runway is self-supporting, with a design that resists lateral and longitudinal forces without assistance. Braces for other support structures aren't required. Because of its independence, the system can be used both indoors and outside. The bridge crane is positioned on rails that run along the tops of the runway beams, enhancing hook height. Top-running freestanding bridge crane runways can likewise carry more weight than underhung variants.

Semi-Freestanding Crane Runway

EOTCRANEKIT can attach the columns and runways to these buildings if they have enough reserve capacity to resist the longitudinal (along the length of the crane runway) and lateral (across the breadth of the runway) stresses. This reduces the amount of steel necessary to manufacture an overhead crane system.

Freestanding Header-Braced Crane Runway

The runway is supported by freestanding support columns, each of which has a header connecting them. When the lowest impediment in the building is high enough to not limit the hook height, header-braced systems are ideal. This runway can accommodate numerous bridge crane systems and is easily extendable.

Knee-Braced Crane Runway

Supports for knee-braced crane runways are directly attached to a 6 inch concrete slab or reinforced concrete footers. When enough floor space is available, these low-maintenance runway crane systems provide unequaled hook height.

Underrunning Crane Runway

Underhung crane runways are generally lighter than top running systems, allowing for greater mobility and utility. Underhung runways can be suspended from the ceiling because they are significantly lighter. They can also run side by side without interfering with one other. Underhung crane systems also have the mechanical advantage of being able to link numerous systems, allowing operators to transfer loads between them. They can also be interlocked with monorails to allow items to be transported along a predetermined course.

Underhung Freestanding Runway

The bolt-together construction of underhung freestanding runways eliminates the need for a certified welder during assembly. An underhung crane's capacity to interlock with a fixed spur, crossover, and nearby cranes is one of its most significant advantages. This interlocking capacity allows a load to be carried throughout the plant system without having to be set down, reducing the requirement for re-handling.

Ceiling-Mounted Crane Runway

Ceiling mounted structures/runways can be employed in constructions that have been engineered to resist the extra stresses from overhead cranes. Under hanging crane systems with capabilities of 5 tons or less are often acceptable for these systems. Ceiling-mounted systems are ideal for maintaining shop floor space free of columns and providing a wider hook coverage area than freestanding systems.

Underhung overhead crane runways are attached directly to a building's ceiling or roof structure with underhung ceiling-mounted runways. Ceiling-mounted, underhung systems are exceedingly adaptable, and transfer switches can be used to efficiently shift loads from one bay to another. Crane runways that are suspended from the ceiling can also make use of the complete floor space beneath the crane runway.

Workstation Crane Runway

Free Standing Workstation Crane Runway

The purpose of a free standing bridge crane is to support weights that are moved both vertically and horizontally and to be bolted to the floor. Inside a closed system, one person can maneuver the cargo along a number of tracks, including curves and monorails. When there isn't enough headroom or the ceiling isn't sturdy enough to support a mounted bridge crane, this design works effectively.

Ceiling-Mounted Workstation Crane Runway

Ceiling-Mounted Workstation Crane Runway

Bridge cranes that are suspended from the ceiling are ideal for applications that require a lot of mobile equipment, have limited floor space, or may alter in the future. Moreover, ceiling-mounted systems make it simple to increase the number of bridges, the length of the runways, and the connections between monorail crane systems.

Crane runway inspections

Overhead crane runway systems are subjected to constant stress and wear forces, resulting in operational and safety difficulties over time. As a result, inspecting crane runways and their supporting systems is equally as critical as inspecting the cranes and hoists that use them.

What is checked during a typical inspection?

A typical runway inspection consists of a visual assessment by a competent expert to identify conditions that may necessitate repairs or additional investigation.

An engineering analysis or an alignment/elevation survey are not part of a standard runway inspection. These services would be used to determine the root causes and possible remedies for specific deficiencies discovered during the inspection.

An Inspector conducts a thorough visual inspection of the runway supporting structure from the ground to the crane rails, including rail and rail fastening system runway girders, girder and column tiebacks, girder seats or stools, bracing, columns and column bases (if applicable), runway end stops, hardware (missing and/or loose), and grout.

To guarantee that there are no deficiencies, the whole length of both runways must be reviewed. Each piece of rail attachment hardware is normally inspected to verify it is not loose and has to be replaced. Defective items or places are typically identified in the field and reported in the report.

Safe access with a lift is typically impractical or impossible due to racking, inventory, and process equipment. This necessitates the Inspector "walking the runway." A properly designed and installed runway fall prevention system must be installed in these instances to allow the Inspector to safely travel the length of the runway.

Crane runway and crane steel structure

Crane runway and crane steel structure

Crane runway and crane steel structure

Crane runway and crane steel structure

Common conditions found during and inspection

- Runways may have been installed incorrectly, with rails not meeting CMAA and AISC standards.

- Nuts and bolts, as well as other components of the runway system, can loosen and fall to the ground, posing a hazard.

- A loose rail attachment bolt or clips might cause the runway to become misaligned.

- Missing or loose rail splice bars can cause adjacent rails to gap, causing bridge wheels and bearings to wear out.

- Excessive rail wear can indicate a problem with the crane's alignment and can lead to wheel wear.

- Over time, rail tiebacks might wear out and break, producing runway alignment concerns and perhaps girder failure.

- Cracks or other stress-related failure signs can appear on runway girders.

- Mishandled goods or ground-based equipment can destroy runway columns.

- The bases and shelves of runway column bases and shelves might deteriorate with time, causing elevation concerns.

How often should crane runway inspections be performed

Crane runway checks should be performed at least once a year as part of every crane system's normal safety and operational review.

Contact us if you need help with Crane Runway Design, Runway System Inspection, Alignment Survey, or Engineering Analysis.

What Is a Crane Runway?

A crane runway structure is a component of an overhead crane structure that provides both vertical and horizontal support for the overhead crane. A crane runway consists of the columns that provide vertical support for the bridge girder(s) as well as the rail that it travels on. A crane runway also supports the crane's framework, which includes the rails and brackets. A crane runway is typically made of a rolled section of I-beam, a welded I-beam, or a box girder. A crane runway system is frequently used by jib cranes, workstation cranes, monorail systems, bridge cranes, and both top-running and under-running cranes.

What Is the Function of an Overhead Crane Runway?

A crane runway structure is an essential component of an overhead crane. It is made up of the bridge girder, which supports the type of hoist and trolley being utilized, as well as the vertical and lateral supports (columns and runway beams). Although there are many different types of overhead cranes, the following are the most popular:

- Top Running Bridge Crane Runway -A top running crane runway is one of the most common type of overhead crane utilized in industry and transportation. Top running crane runways come with an immovable rail attached to each beam. This rail is used by end trucks to move the bridge and hoist along the crane runway. Top running cranes can be built with a single girder or two girders.

- Semi-Free Standing Overhead Crane Runway -A semi-free standing crane runway makes use of the building's own strength to help sustain the overhead crane's lateral and longitudinal forces. Semi-free standing crane runways are more economical than other types because they use less steel.

- Underhung Bridge Crane Runway -An underhung crane runway uses a rail installed beneath the runway rather than on top, similar to a top running crane runway. Due to its improved working range, this underslung crane is perfect for locations with limited headroom. Since a top mounted crane runway is impractical, underhung crane runways are typically employed because they are less expensive to build.

- Free Standing and Semi-Free Standing Bridge Crane Runway -A self-supporting overhead crane runway, also known as a free standing crane runway, is a very versatile type of self-supporting overhead crane that can be situated indoors or outdoors. For instance, a gantry crane normally travels along a track and is supported by free-standing legs. At large production facilities, free standing crane runways are popular, as are semi-free standing runways that use the building structure for support.

More on crane runway and runway beams https://www.eotcranekit.com/blog_parts/crane-runway.html

How is a Overhead Crane Runway Built?

The parts of a crane runway vary according on the design, however they always start with the columns. A professional eot crane engineer built the columns to meet the OSHA standard, and they are typically set in concrete. Jib cranes, for instance, are frequently set in concrete because they do not rely on building columns unless those are available. Installations start with a structural survey to make sure the building is robust enough to sustain the semi-free standing runways in part.

Crane runway alignment specifications are quite detailed and must be followed precisely to avoid early runway breakdown. In fact, since normal building steel is not made for precise tolerances, even the steel itself must be specially produced. Because of its structural strength and ability to be precisely milled, wide flange I-beams made for crane runways are frequently utilized as the runway beam/girder.

What Are the Safety Requirements for Crane Runways?

Safety of the overhead crane is essential for the fall protection it offers. Seasonal fluctuations in air temperature cause the parts of a crane runway to constantly expand and contract. These forces can lead to misalignment of the end trucks with the rail, which results in excessive wear whether the crane runway is supported by a building or stands alone.

Overhead crane runways must thus be checked for flaws and wear on a yearly basis by a structural engineer with certification. The fasteners on the rail, columns, and end stops might become loose during normal runway operation, so these components of annual maintenance are also included. Any overhead crane system with a runway must undergo annual maintenance and inspection, such as:

- Top Running Single Girder Overhead Crane

- Top Running Double Girder Overhead Crane

- Underhung Overhead Crane

- Semi-Free Standing Overhead Crane

- Free Standing Overhead Crane

- Cab Operated Overhead Crane

- Jib Crane

Annual inspection is required for overhead cranes employing the following components:

- Runway Girder (including Box Girders)

- Runway Column

- Runway Rail

- Hoist

- Bridge Girder

- End Trucks

- Trolley

- Load Blocks (including the hook, swivel, sheaves, pins, and bearings)

The professional OH crane operator must calculate crane loads and crane tolerances and adhere to them. Any crane's load capacity, which is the crane's maximum load rating, will be noted on the equipment itself. The maximum load that a bridge crane can support in a particular configuration will be determined using a load chart.

Is your crane traveling correctly on the runway?

Overhead cranes should travel or move along their runway rails with as little skew and as little binding as possible. Improper tracking causes premature wheel and rail wear, which leads to expensive repairs and downtime, as well as inefficient and suboptimal crane operation. There are numerous reasons why a crane does not travel properly on the runway, as following:

- A worn-out or misaligned rail.

- Clips missing.

- worn-out pads

- Corrosion.

- Improper installation .

- Column settling, overloads, or impacts have caused the runway structure to be uneven, distorted, or twisted.

Crane runway services for your overhead cranes and gantry cranes

We understand that the efficiency of your crane runway system determines the reliability of your overhead travelling crane. Our engineering expertise benefits our clients in the following ways:

- Runways Design - We think it makes sense for the engineers who build your overhead crane to also design the structure of your crane runway. Your bridge crane runway designs are made using CAD technologies by our structural and mechanical engineers. Check how to measure your overhead crane runway size?

- Runways Fabrication - Our runway structures are built with the same durability as our material handling cranes. Frequently, the same welders and craftsmen that construct your crane also create the runway construction.

- Runways Installation- A crane system runs smoothly if the runway structure is placed properly. Our installers are runway specialists with years of expertise and hundreds of installations; they have developed unique abilities and special gear to make installs quick and easy.

All of our designs are provided with the engineering calculations needed to get regional building permits or professional engineer certification.